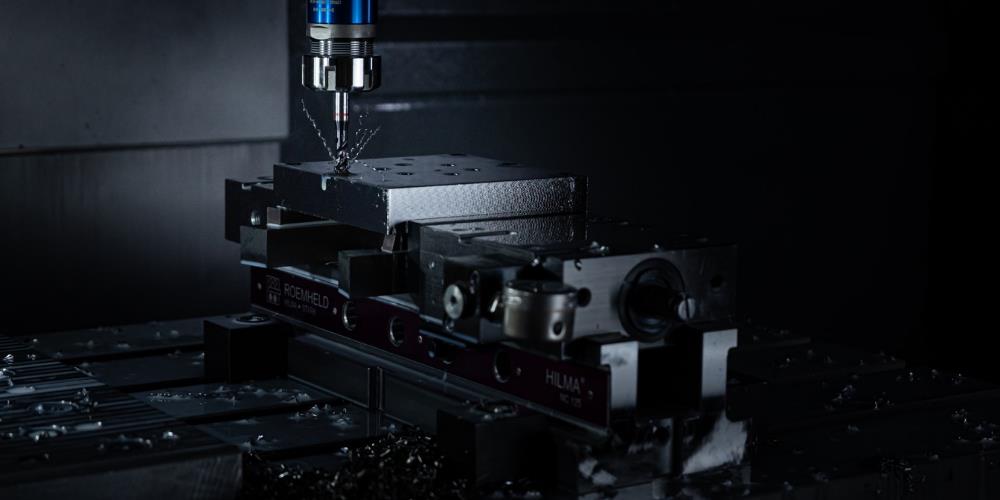

The milling process has evolved with the introduction of computer numerated control, better known as CNC Milling. This milling service is a robotic version of milling where machine operators program a machine to bring out the milling processes. This change implies that machining and milling have become more stable and automated when it comes to accepting input from Computer-Aided Design software and transforming it into digits - which control the movement of the cutter of the engine. They rely on the nature of the produced product and the material being utilized. However, all these CNC Milling Machines can be categorized based on their underlying technology and working processes. So, what type of CNC milling machine is most suitable for making your particular product? Find it out below.

Vertical CNC Milling Machine

The direction of the mill being utilized holds an exceptional impact on the output. In this type of CNC milling machine, the spindle axis on the mill is vertically positioned. Milling edges are placed on the spindle of the vertical mill, letting the apparatus efficiently cut into the material as required. Also, note that vertical milling operations have the tooling process running diagonally. Besides, a vertical CNC machine usually has three axes where the tooling progresses vertically. The table runs from the back to the front of the machine and from side to side. The milling cutter’s body, pitch, and altitude are all conditional on creating the type of product.

Horizontal CNC Milling Machine

Horizontal mills work practically similar to vertical mills. However, the movement of the cutters is mounted on a flat arbor, and the tooling spins horizontally. Rather than drilling into an entity, a pavilion shaves disfavored stuff from a project off. That is why it’s horizontal instead of perpendicular or vertical. Horizontal milling machines also contain a universal table, which lets the product be cut at different angles and drops to the versatility of the machine settings. Besides, horizontal milling machines will usually include a fourth axis for rotation. For production, this machine likewise has a pallet changer. It has two working areas. One where the elements are being treated. The second is where an operator can work on the subsequent set of those elements.

Multi-Axis CNC Milling Machine

Another best type of CNC milling machine is multi-axis milling. The name hints that it holds many axes and is versatile to perform particular operations. Each added axis represents an added type of action. Going to exterior three-axis devices smoothly extends the capability of a CNC machine. Generally, matching the sophistication of the element to the intricacy of the machine is the soundest practice. It doesn’t make it logical to create a low forbearance / no-frills part in a five-axis milling machine. Besides, the improved efficiency of taking more axes produces an expense savings benefit - for instance, simple machine set-up & smooth programming.

Conclusions

So, these are the most familiar types of CNC milling machines that are pretty popular in today’s milling service. The preference of devices relies on the kind of employment, the precision required, the task budget, and the time available to accomplish the task.